Validation Services

Precision, Reliability, and Compliance

Explore

THERMAL VALIDATION SERVICES

At CYMAX LABS Pvt. Ltd., we take pride in offering a comprehensive suite of validation services designed to elevate the reliability and compliance of your critical processes. Our team of seasoned experts is committed to ensuring that your systems, equipment, and environments meet the highest standards, providing you with the confidence to excel in your industry.

Our Validation Services Include:

THERMAL VALIDATION :

Stability Chambers Validation:

Ensure the reliability and performance of stability chambers crucial for product storage and testing.

Refrigerators Validation: Calibration and validation services for refrigeration units, preserving the integrity of temperature-sensitive materials.

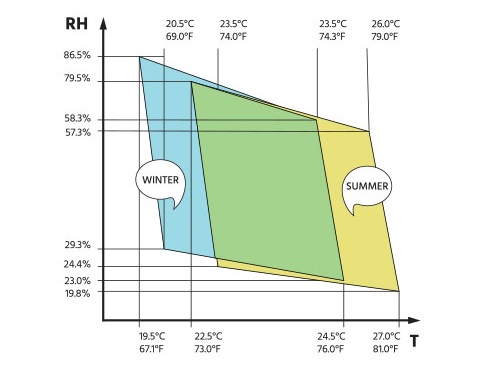

HVAC Validation:

Achieve HVAC system precision with our Validation services. We rigorously assess and verify heating, ventilation, and air conditioning components for compliance with technical benchmarks. Ensure optimal thermal comfort, air quality, and energy efficiency in your controlled environments.

Hot Air Ovens Validation: Specialized validation of hot air ovens, ensuring precise temperature control vital for numerous industrial processes.

Tray Dryers Validation: Guarantee optimal performance in the drying of materials with our validation services for tray dryers.

Cold Rooms Validation: Validation services to maintain the required temperature levels for storage in critical cold room environments.

Deep Freezers Validation: Validation services essential to ensure deep freezers operate at required temperatures for sensitive material preservation.

Vacuum Ovens Validation: Specialized validation for vacuum ovens, ensuring accuracy in maintaining controlled atmospheric conditions.

Incubators Validation: Calibration and validation services covering incubators, maintaining optimal and precise environmental conditions.

Autoclave / Sterilizer Qualification: Ensuring optimal performance and compliance, we conduct thorough validation procedures for autoclaves and sterilizers, confirming their ability to achieve precise temperature, pressure, and sterilization times.

Lyophilizers Qualification: Our rigorous qualification process guarantees the reliability of lyophilizers, assessing parameters like freeze-drying cycles, temperature control, and vacuum integrity to maintain product stability and quality.

Depyrogenation Ovens Qualification: Precise calibration and validation of depyrogenation ovens assure removal of pyrogens. Our procedures focus on temperature uniformity, holding times, and verification of depyrogenation effectiveness.

Depyrogenation Tunnels: Stringent qualification of depyrogenation tunnels involves assessing tunnel parameters like temperature profiles, residence times, and airflow patterns, ensuring complete pyrogen removal in pharmaceutical manufacturing processes.

BOD. Deep Freezers / Walk-In Freezers: Our qualification for deep freezers includes temperature mapping, ensuring uniform and consistent storage conditions. Walk-in freezer assessments cover temperature control, monitoring, and alarm systems for optimal sample preservation.

Photostability Chamber Qualification: We validate photostability chambers to ensure accurate light exposure conditions, monitoring irradiance, temperature, and humidity. This guarantees pharmaceutical products’ stability and integrity during exposure studies.

Steam-in-Place (SIP) Qualification: Thorough validation of SIP systems involves assessing temperature distribution, steam penetration, and exposure times. This ensures effective sterilization of equipment and components critical to biopharmaceutical processes.

Incubators: Our incubator qualification involves verifying temperature accuracy, uniformity, and stability. This guarantees controlled conditions for cell cultures and microbial growth, crucial for research and development.

Washer Disinfectors: Rigorous qualification ensures washer disinfectors meet required standards for cleaning and disinfection. We assess parameters such as water quality, temperature, and detergent concentration to ensure effective equipment decontamination.

CIP Systems: Comprehensive validation of Clean-in-Place (CIP) systems focuses on cleaning efficiency, chemical concentration, and system integrity. This guarantees optimal hygiene in pharmaceutical and biotech manufacturing processes.

Dry Heat Ovens: Validation of dry heat ovens involves assessing temperature uniformity, ramp-up times, and holding times. This ensures effective sterilization and depyrogenation of equipment and components.

Furnaces: Our qualification process for furnaces involves calibration and validation of temperature control, ensuring precision in heat treatment processes critical to various industrial applications.

SIP Systems: Thorough validation of Steam-in-Place (SIP) systems ensures efficient and reliable sterilization of bioprocessing equipment, confirming parameters such as temperature, pressure, and exposure times.

Stability Chamber: Qualification of stability chambers involves monitoring and validating temperature and humidity control. This ensures accurate simulation of storage conditions for pharmaceuticals, supporting product stability studies.

CLEAN ROOM VALIDATION SERVICES

Air Velocity Test: We conduct precise air velocity tests to validate and optimize airflow within controlled environments. By ensuring uniform distribution, we guarantee compliance with industry standards for cleanrooms and critical spaces.

HEPA Integrity Test: Rigorous testing of HEPA filters ensures their integrity and efficiency. Our procedures assess air filtration, leakages, and pressure differentials, ensuring a sterile environment and compliance with stringent regulatory requirements.

Temperature Mapping: Thorough temperature mapping assessments provide comprehensive insights into temperature distribution within controlled spaces. By identifying hot spots and variances, we optimize conditions critical for pharmaceuticals, ensuring product integrity and compliance.

Sound Level and Lux Meter: Our testing employs sophisticated sound level and lux meters to evaluate environmental conditions. This ensures compliance with noise and lighting standards, creating optimal working conditions in pharmaceutical and laboratory settings.

Non-viable Particle Count Test: Utilizing state-of-the-art equipment, we conduct non-viable particle count tests to assess airborne particulate contamination. This ensures compliance with cleanroom standards and verifies the effectiveness of air filtration systems.

Recovery Test: Recovery tests evaluate the system’s ability to return to specified conditions after a disturbance. Our meticulous procedures ensure that controlled environments quickly regain desired parameters, critical for maintaining product quality in pharmaceutical manufacturing.

Airflow Pattern Test: Verification of airflow patterns is essential for controlled environments. Our testing methods assess directional airflow, identifying potential cross-contamination risks and ensuring that cleanroom conditions align with regulatory requirements.

OTHER VALIDATION SERVICES

Clean Rooms Validation: Comprehensive validation services ensuring compliance with industry standards for cleanliness and environmental conditions.

Temp. & RH Validations: In-depth validation covering both temperature and relative humidity, essential for various controlled environments.

Laminar Airflow Validation: Validation services for laminar airflow systems, crucial for maintaining desired air cleanliness levels.

Compressed Air Validation: Specialized validation for compressed air systems, ensuring compliance with industry standards for quality and purity.

Nitrogen Air Validation: Validation services covering nitrogen air systems, guaranteeing the purity and quality required for various applications.

Pure Steam Validation: Ensure the quality and compliance of steam used in pharmaceutical and biotechnological processes with our pure steam validation.

PLC Validation: Validation services for Programmable Logic Controllers (PLCs), ensuring their accurate and reliable performance.

CS VS Validation: Comprehensive validation services for Computer System Validation (CS VS), ensuring the integrity and compliance of computerized systems in regulated industries.

Tunnel Validation: Elevate your production standards with our Tunnel Validation services. We meticulously assess and validate the efficiency of your tunnel processes, ensuring consistent and reliable outcomes. Trust us for precision in temperature control, compliance assurance, and enhanced production integrity.

Room Validation: Step into a realm of confidence with our Room Validation expertise. We specialize in validating controlled environments, ensuring they meet industry standards. Our meticulous assessments guarantee optimal conditions for processes, compliance with regulations, and a secure foundation for your operations.

Why Choose Us?

Our validation services are not just about compliance; they are a commitment to excellence. Partner with us to elevate the accuracy and efficiency of your critical processes. Contact us today to discuss your validation needs.